Why Installation Details Matter ?

Even the best hygienic materials can fail if they are not installed correctly. Improper gaps, sharp corners, and poor sealing create micro-environments where dust, moisture, and bacteria thrive.

- In sensitive sectors like medical, food, and pharmaceutical, these oversights can lead to:

- Contamination risks

- Regulatory violations

- High maintenance costs

- Shortened material lifespan

That’s where hygienic installation accessories come in—and where we deliver unmatched attention to detail.

Hygienic Accessories We Use And Why They Matter

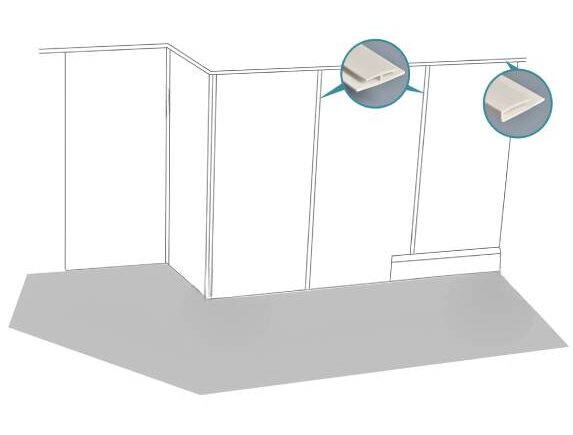

✨ H-Section: Seamless Wall-to-Wall Connection

The H-section is used to join two wall panels securely and hygienically. It provides:

- A tight seal that eliminates gaps between panels

- A smooth, easy-to-clean transition

- Prevention of dust and bacteria accumulation between panels

- Compliance with ISO 22196 antimicrobial standards when used with products like Saniclad or Biomax

“We don’t leave even a millimeter open our H-section installations make sure no microbe finds a hiding spot.”

✨ J-Section: Hygienic Wall-to-Ceiling Integration

The J-section ensures a smooth, clean transition between the wall and ceiling, removing 90 degree angle traps where microbes could accumulate.

- Helps prevent ceiling condensation from entering wall panels

- Creates an aesthetically curved finish

- Reduces shadow lines and dust collection zones

- Enhances airflow and light distribution in clean rooms

✨ Thermoforming: Curved Angles for Cleanliness

Sharp corners and rigid angles invite microbial buildup. That’s why we use thermoforming a process where PVC wall panels are heated and reshaped into curved corners and junctions.

This advanced technique:

- Ensures continuous, jointless wall-to-wall or wall-to-floor transitions

- Makes sanitation easier by eliminating inaccessible edges

- Is ideal for operating rooms, ICUs, and food processing clean zones

“With thermoforming, we reshape the wall—not just for design, but for infection control.”

✨ Welding Rods: For Seamless Jointing

Instead of leaving tiny lines or using caulking that degrades over time, we use welding rods to bond wall panels together. This creates a permanent, waterproof, and bacteria-resistant weld.

Benefits include:

- No loose accessories or visible seams

- Consistent antimicrobial protection throughout

- Compliance with international cleanroom standards

Designed to Seal Out Risk

By using a combination of H-sections, J-sections, welding rods, and thermoformed edges, we create a completely sealed hygienic envelope. Every angle, joint, and junction is engineered to ensure:

- No open crevices

- No dust or fluid traps

- No compromise to hygiene or durability

This approach is especially critical for:

- Hospitals and ICUs

- Pharmaceutical cleanrooms

- Airline catering kitchens

- Food & beverage production zones